Dubai Watch Week spotlights German watchmaking

One of the primary aims of the Dubai Watch Week is the preservation and transmission of horological knowledge. While most of us equate high-end watchmaking with the Swiss, the German horological industry is also equally skilled in haute horlogerie. Dubai Watch Week organised a Press Trip themed “Saxony – the heart of German watchmaking”, to discover the heritage, skills and craftsmanship of watchmaking in Saxony, especially in Dresden and Glashütte

“Day & Night” magazine had the opportunity to sit down for a chat with Christine Hutter – Founder and CEO of high-end independent watchmaker Moritz Grossmann – and Marco Lang – Founder, Lang & Heyne.

Moritz Grossman: master of finishings

Christine Hutter, founder and CEO of high-end independent watchmaker Moritz Grossmann, speaks about the brand, its obsession with high-end finishing, and the growing recognition of German watchmaking skills…

How long did it take to set up the manufacture and how hard was it?

We established the company in 2008; now we have our manufacture and 50 people working here. We are still in set-up process; we started in 2009 as a small workshop and then we slowly expanded, buying new machinery, setting up new departments. It has been an on-going process and today we are producing nearly 85 per cent of our movements in-house.

It was hard but I had a very good team to support me. You can do nothing without a dream team behind you, and everybody worked hard to improve their respective departments. But the growth of any company is in waves; it goes through ups and downs. Now we are on our way up; we produce less than 500 pieces but the quality of our pieces is very, very high, so we are happy and look forward to the future.

Why is that nearly one-third of the employees in your manufacture are specialists in finishings?

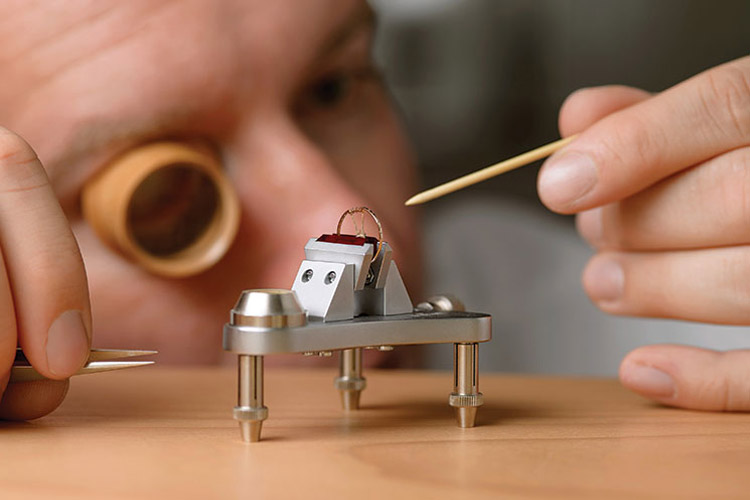

If you look at the watches we make and the process of watchmaking in our manufacture, the price of the watch will not even be a consideration as the finishing of our watches is so good. We work in the old traditional ways of finishing, and we also ensure that each and every part, however small, of the movement is hand-finished. We do not want to mechanise any part of the process as we want really high artistic craftsmanship in our watches.

When do you think that German watchmaking will be appreciated as equal to Swiss brands not just by watch aficionados but also by the general public?

I think this has already started because Glashütte has a special cachet today in the world market. It is true that collectors worldwide know what is happening in Glashütte and the work of German brands. But to compare it with the Swiss brands is difficult because we started watchmaking again here only 25 years ago, whereas modern Swiss watchmaking is more than 80 years old. This is our 10th anniversary, so we are one of the youngest brands here in Glashütte. We have a number of watchmakers here, catering to a wide range of price points, so now not only horologists, but the general public is also aware of Glashütte’s watchmaking expertise.

Famed watchmaker Philippe Dufour recently remarked that German watches are way above the Swiss watch industry – your comments?

We are also in touch with Philippe; he is very complimentary of our work, especially our finishings, as it is very similar to the kind of finishing he does. When you look at our watches, they are very simple and classic, but inside, our watches are high complications and the finishings are detailed and intricate. We also try to develop features that are useful for our end clients and they are service-friendly. I think Philippe likes all of these; when I spoke with him he said that only a few brands – mainly his and ours –engage in that high level of finishing.

What is the ideal number that you think you need to produce and still remain exclusive for your brand?

Somewhere around 800 to 1,000 pieces would be the ideal number because we would like to keep our craftsmanship – keep it in-house and hand-made. We do not want to mass-produce or automatise our production at any point.

Do you plan to bring out more complications such as the Skylife Benu Tourbillon that you unveiled three years ago?

We do have a few complications, but it take years of work for the development and construction of the movement. The tourbillon was special, with its human hair, seconds stop, flying tourbillon, and the two buttons in the movement. We also have smaller complications such as power reserve and date. We have now introduced the prototype of our special automatic movement, the ATUM Hamatic, which utilises the automatic hammer and not the rotor. We are developing other complications such as an automatic watch, perpetual calendars, and chronographs. We want to develop them in a different manner so that it will be simple to look at and easy to handle.

Lang & Heyne: making simple complications

Marco Lang explains how the marque established itself in the niche world of high-end watchmaking and what makes it stand out in a demanding market.

How did you establish your reputation as a master watchmaker in the competitive world of haute horlogerie?

Lang & Heyne is a small niche brand, and not a competitor for the big brands. We cater to customers who are looking for high-quality watches. We do not advertise, but we do communicate. Some of the independent brands forget to communicate about their work and brands; they think it is enough to just make nice watches and go to Basel to be successful.

I had been involved with the AHCI – Académie Horlogère des Créateurs Indépendants – and it was my first choice of marketing. It was in 2002 that we presented our first models, and we launched them using the AHCI platform. This gave us legitimacy and enhanced our appeal to other watchmakers and watch aficionados. For instance, Philippe Dufour came over with his team and retailers, and while talking to them described me as a young watchmaker.

We have been making new calibres every two years and our communications has also increased proportionally. We use social media to spread the word, as print media is so expensive. It was initially surprising for us that we went to the fairs and instantly sold our watches. My inspiration is the pocket watches historically made in Saxony and so my watches are more of pocket watches that translate into wristwatches.

In 2001, I teamed up with watchmaker Mirko Heyne to start the brand. Our watches are very simple and not complicated. In the beginning, we did not have all the equipment we have today; so we used Unitas movements and parts, and only did the finishings. For some reason, it clicked and people really liked our watches.

We then had a difficult period; all our watches were prototypes, but we now suddenly had to make a number of such watches. Though we were successful, it was then that Heyne left. He comes from the luxury watchmaking field and favoured that kind of products, while I preferred the classic style and simple looks. So we parted ways one year later.

But the brand still carries his name?

Yes, we still carry his name. He has contributed to the brand initially and also once we had made a name for ourselves, it would not be wise to change it a year later.

Since you specialise in detailed finishing, how do you arrive at the pricing for your watches?

The way we calculate is different from the other brands; normally high-end brands arrive at an overall figure as marketing costs a lot and retailer margins are more. Whereas I calculate the actual costs such as material, labour, etc., and add a retailer margin and a 20 per cent margin for us and that is the price.

Is the company breaking even?

Normally yes, but some years we have to invest more capital to buy new machinery, etc. Overall, we are doing well but we cannot afford to spend more on retailer margins or advertising. In some ways we have more freedom than the big brands, but in other ways we are more constrained.

Can you tell us about how the Augustus was conceived and developed?

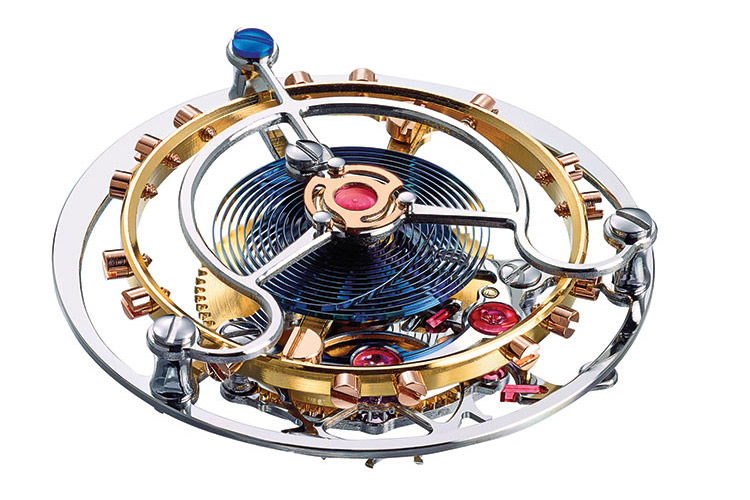

The inspiration for the Augustus watch came from one of our customers; his problem was that he could not remember the birthdays, anniversaries, etc., of his family. Our mandate was to make something similar to the iCalendar by Apple, but on a mechanical platform. For nearly one-and-half years, I was playing with ideas on how to present it; the mechanical side would come later. How would I show the age, year, etc., on a watch was the question. It took us three years to develop it.

Now the customer can give us 12 events – anniversaries, birthdays, or founding dates of companies, etc. Once these are entered, he then gets reminders on the dial of the watch. Because we use only one button and one crown to enter this data in the watch, it is complicated to make. The crown has 5 different modes – to set time, date, event, or to wind, and so on. The most complicated function of the watch is that it calculates the age of a person in any given year. We are able to make one Augustus watch per year.