In October 2022, Chronométrie Ferdinand Berthoud unveiled the Chronomètre FB 3SPC, the third pillar of its collections inspired by and following in the tradition of the famed 18th-century watchmaker for whom the brand was named. The FB 3SPC incorporates key elements of marine chronometers such as those produced by the historical atelier of Ferdinand Berthoud, one of those elements being the cylindrical hairspring. We bring you the details…

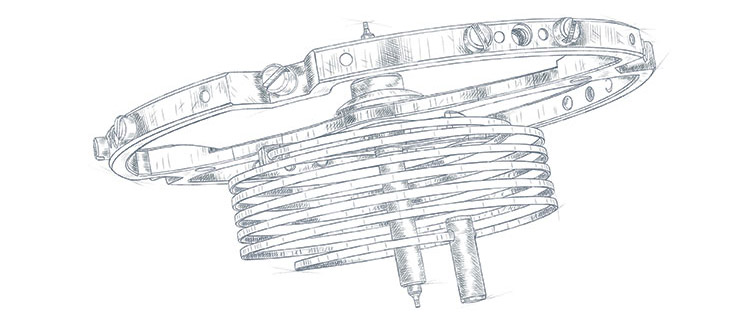

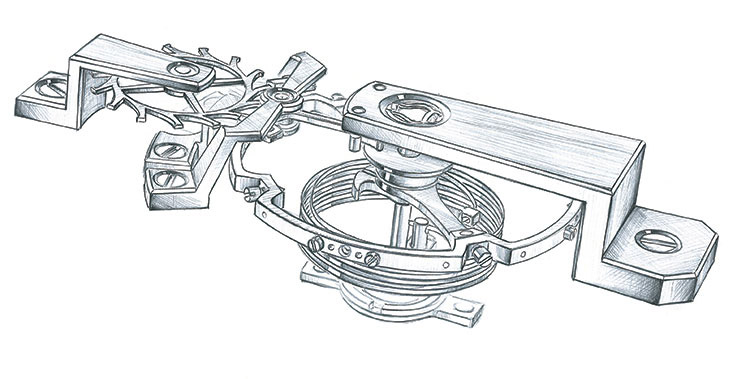

Cylindrical hairsprings, as opposed to the more familiar flat spiral hairsprings, are particularly associated with the precision timekeepers used in marine exploration, due to their greater stability and isochronism. However, their use is not well adapted to wristwatches since their size and form can introduce chronometric error when the watch is in the vertical position. Chronométrie Ferdinand Berthoud undertook three years of research and development to create the FB 3SPC, the first and only wristwatch with a cylindrical hairspring that has been officially certified as a chronometer by the Contrôle Officiel Suisse des Chronomètres (COSC).

The origins of the Chronomètre FB 3SPC lie in the No. 26 decimal watch made in 1793 by Louis Berthoud, Ferdinand Berthoud’s nephew and successor. This was a high-precision pocket chronometer with a cylindrical hairspring, a feature highly appreciated and championed by Louis Berthoud, who frequently implemented it in the timepieces that he personally considered as his best creations.

One of the principal factors determining the ability of a hairspring to measure time precisely is how it develops – or “breathes” – when energy is supplied to it via the movement gear train. A hairspring that develops concentrically, maintaining the same centre of gravity throughout its period of oscillation, is more mechanically stable, subject to fewer perturbing forces while in operation, and therefore more reliable. A hairspring that develops irregularly, with inconsistent spacing between its coils or with uneven expansion and contraction patterns, leads to a shifting centre of gravity. This, in its turn, introduces friction at the balance pivots, disrupting the overall chronometric ability of the watch, especially when the mainspring barrel is near the end of its power reserve and the balance exhibits low amplitude.

Due to its form, which consists of a series of diametrically congruent coils, a cylindrical (or helical) hairspring has far greater potential to develop concentrically than a flat spiral hairspring. It was established horological knowledge, however, that this was only true in the horizontal position, when the axis of the cylindrical hairspring was perpendicular to the ground. In the vertical position, the increased mass of a cylindrical hairspring compared to a flat spiral hairspring could theoretically multiply the rate of chronometric error. In a practical sense, this meant that cylindrical hairsprings were unsuitable for use in wristwatches, since their chronometric advantage would only be manifested if the watch was always kept in the horizontal position.

At Chronométrie Ferdinand Berthoud, this was not seen as a dead-end conclusion, but as a portal that opened onto an unknown land, ripe for exploration. President and founder of Chronométrie Ferdinand Berthoud, Karl-Friedrich Scheufele recalls how being told that it would be impossible to achieve chronometer certification with a cylindrical hairspring was all the impetus they needed to accept the challenge.

Adapting the cylindrical hairspring for the wristwatch

Mechanical horology is a métier that has existed for half a millennium, and there are established standards and processes for almost every aspect of watchmaking knowledge. Libraries of data and analyses are available on any subject conceivable, even esoteric areas such as the optimal chemical composition of hairsprings or the thermal expansion coefficients of various alloys.

In all this wealth of information, the one topic that remained dark, an unmapped terrain that confounded the research and development team at Chronométrie Ferdinand Berthoud, was the question of how to adapt a cylindrical hairspring for a wristwatch. The team knew that the geometry of the hairspring itself was the most important part of the equation that would result in a chronometer-certified wristwatch with cylindrical hairspring, but everything else was a mystery.

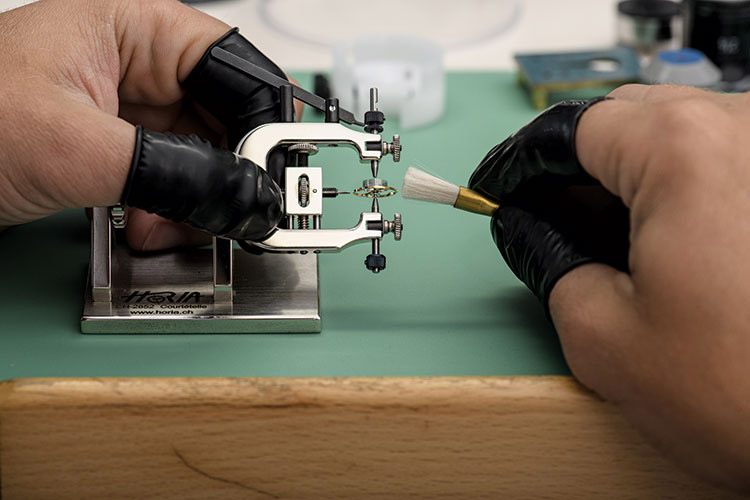

The first tests at Chronométrie Ferdinand Berthoud were conducted with a cylindrical hairspring with purpose-designed terminal curves, though not yet assembled within a movement. The isolated hairspring performed according to all expectations, but once the hairspring was pinned to its collet in preparation to mount it within the movement, the team noticed that the hairspring exhibited a tendency to “breathe” asymmetrically – a response to the additional mass of the pin and collet. The obvious solution was to reduce the weight of the collet and re-centre the hairspring’s centre of gravity.

As in a carefully balanced mathematical formula, changing one variable involves adjusting the others as well. Reducing the weight of the collet necessitated redesigning the terminal curves. This changed the inner attachment point of the hairspring, which in turn required a re-engineering of the collet profile itself, so that both the inner and outer attachment points of the hairspring maintained the correct angular displacement in relation to each other. It took over three years of careful study and experimentation, three years of simulating hairspring terminal curves and building a solid foundation on which to base the new Chronomètre FB 3SPC.

Chronomètre FB 3SPC

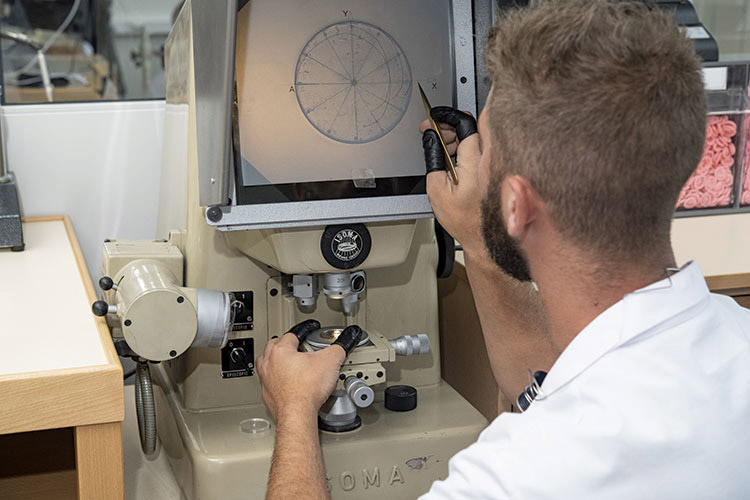

With the FB 3SPC, the research and development team at Chronométrie Ferdinand Berthoud were obliged to start with a blank slate, given the scarcity of established studies in the area of regulating cylindrical hairsprings. Taking cues from Ferdinand Berthoud himself, whose horological experiments and assays were a key part of his work, the Chronométrie Ferdinand Berthoud team adopted the scientific method: hypothesis, testing and iterative refinement.

Creating a roadmap that shows how to obtain COSC certification for a wristwatch movement with cylindrical hairspring requires deliberate and meticulous steps. As there is no textbook on adjusting a cylindrical hairspring and balance, each completed FB 3SPC requires a master’s touch, a master’s perspective, and a master’s experience. The ultimate aim is perfection: in mechanical construction, in energy equilibrium, and in chronometric performance.

The results have spoken for themselves. As of 2023, every single movement created for the Chronomètre FB 3SPC has individually achieved COSC certification. On average, the COSC-tested movements exhibit a daily rate of 2.08 seconds per day, falling within the optimal middle zone of the COSC-mandated margins of -4 to +6 seconds per day. On an individual basis, the daily variation for 80 per cent of tested movements is between -1 and +3 seconds per day, exceeding COSC precision standards by a factor of 2.5.

The Chronomètre FB 3SPC is a tribute to the patrimony and spirit of the eponymous watchmaker, both in embodying the principles of precision horology and in expanding the world of mechanical knowledge.