Inspired by the architectural philosophy of habitology that developed in the 1960s, MB&F’s latest Horological Machine Nº11 Architect is the answer to Maximilian Büsser’s question, “What if that house was a watch?” With its latest creation, MB&F further blurs the line between the two, and the result is the grey of steel rebar, the grey of freshly sprayed concrete

Habitology moulded space around the form of a human body, the spherical scope of vision perceived by the human eye, the radial ambit of human limbs moving through the air, the roundness of the breath that inflates our lungs and creates ephemeral vapour halos on car windows in winter.

In the HM Nº11 Architect, a central flying tourbillon forms the heart of the house, pushing skyward under a double-domed sapphire roof. Its quatrefoil-shaped upper bridge recalls the shape of clerestory windows in some of humanity’s greatest temples to its Creator, or perhaps the shape of a zygote undergoing cell division at the moment of conception. From this spinning core, four symmetrical volumes reach outwards, creating the four parabolic rooms of the house that is HM11 Architect.

Turn the house to access each room; the entire structure rotates on its foundations. The 90° angle of offset between each room means that you can position HM11 with one of its rooms directly facing you, or with one of the corridors of the house running towards you and rooms obliquely to each side. This versatility in display orientation also has a practical use. HM11 Architect is an energy-efficient construction – each 45° clockwise turn is signalled by a tactile click under the fingers and delivers 72 minutes of power directly to the barrel. After 10 complete rotations, HM11 is at its maximum autonomy of 96 hours.

While all four rooms share a similar interior – glossy white walls with a full sapphire crystal windowpane – each of them has a different function. The time room is where you go to retrieve the hours and minutes. Rod-mounted orbs serve as hour markers, using larger and lighter polished aluminium orbs for each quarter and smaller and darker polished titanium orbs for the rest. Red-tipped arrows point to the hours and minutes, providing a rare accent of colour to the otherwise Spartan time room.

The next room, 90° to the left, is where the power reserve display resides. Following the design schema established by the time room, rod-mounted orbs are paired with a red-tipped arrow to show how much running autonomy is left in the HM11 barrel. Proceeding clockwise, the five orbs increase in diameter until the final polished aluminium orb, 2.4mm in diameter, indicates the full 96 hours of power reserve.

An instrument rarely seen in horological contexts is installed in the next room – a thermometer. HM11 uses a mechanical system of temperature indication with a bimetallic strip. This mechanical system functions without any external energy input and is available in Celsius or Fahrenheit display variations.

One last room remains, a white void, its only aesthetic feature is a tiny round badge engraved with the MB&F battle-axe motif, set into the sapphire-crystal window. This functions as the time-setting crown of HM11. Pull on the transparent module, and it opens with a click. The front door and key to HM11, you can turn it to relocate yourself in time.

While the peripheral rooms of HM11 are surrounded by exterior walls of polished grade-5 titanium, the central atrium is open to the light, covered by a double-arched sapphire crystal roof. Underneath, the in-house HM11 engine hums away, its cadence set by the 2.5Hz (18,000 vph) balance of the flying tourbillon. Plates and bridges are PVD-coloured, in ozone blue or solar hues of 5N gold, limited to 25 pieces each for the two launch editions of HM11.

The two launch editions of HM11 Architect are in titanium and sapphire crystal. The lower half of the HM11 case is a highly three-dimensional Grade-5 titanium shell with different inner and outer surface profiles. The upper caps of each of the four HM11 rooms are machined separately since they can be affixed only after the movement has been installed. Close to a week is required to complete the HM11 case.

The Horological Machines of MB&F have a reputation for increasing the sophistication of shaped sapphire crystal components used in watchmaking. There are six externally facing sapphire crystal components in the case of HM11, the largest of which consists of two separate sapphire crystal domes stacked concentrically to form the transparent atrium roof of HM11.

An unprecedented feature in watchmaking is the see-through crown, close to 10mm in diameter, that allows an unimpeded view directly into the movement. A crown of this size in sapphire crystal, comes with specific technical challenges to be overcome. In HM Nº11, a conventional gasket sized in proportion with the crown five times bigger would have generated so much friction that the crown would essentially have braked and been unusable. Instead, two sets of gaskets are used, similar to a double airlock security system in spacecraft or submersibles.

Towards the outer edge of the watch, a large low-friction gasket creates just enough of a seal to stop dust from entering via the sapphire-crystal window. A watertight gasket, much smaller in diameter, is located closer to the centre of the movement, surrounding the crown axis. A total of 8 gaskets are dedicated to the sapphire crown alone. Ensuring the integrity of the case and the movement within are in fact a total of 19 gaskets, necessitated by the complexity of the case and its various external components.

The largest gasket used in HM11 Architect is of O-ring construction, shaped in all three dimensions and placed between the case and the bezel. A custom mould was cast for this one gasket; together with the 18 others, it delivers a purpose-engineered solution as a guarantee that the HM11 house remains safe from the elements, with a water resistance rating of 2ATM (20 metres).

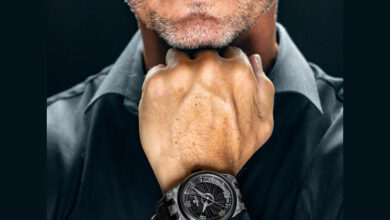

Despite its 3-dimensional, architectural conception and the complexity of its movement, the HM11 measures only 42mm in diameter. It sits sleekly and comfortably on the wrist, thanks to the curved case feet that are also the strap attachment points. These allow the watch to fit a variety of wrist sizes – and also provide stability when the case is turned to wind the barrel.

The barrel is invested with energy through incidental kinetic action (in conjunction with an automatic winding system) or deliberate manual input (via the winding crown). These two methods of supplying energy are combined in HM11 and is amplified; instead of turning a crown of small diameter, you turn the watch itself, adding greater weight to the relationship between HM11 and its wearer. With HM11, its 96 hours of power reserve can be completely rewound after just 10 full clockwise rotations of the case.

The flying tourbillon that controls the timekeeping ability of HM11 Architect is the same as those appearing in Horological Machines 6 and 7, as well as Legacy Machine FlyingT. Its large balance wheel boosts the overall inertia of the system, offering benefits in terms of chronometric stability, but tourbillons (and flying tourbillons in particular) are vulnerable mechanisms, susceptible to shocks that can interfere with performance. Conventional shock-protection solutions in watchmaking are designed to protect specific components, notably wheel pivots, whereas general shock-proofing solutions that shield the entire movement are uncommon. Rather than applying additional shock-proofing elements to individual watch components, HM11 incorporates a full-system dampener, consisting of four high-tension suspension springs that sit between the movement and lower-case shell.