OMEGA Manufacture, a masterpiece of efficiency

OMEGA Manufacture

It was in 1882 that “Louis Brandt & Fils” first moved to its watch-manufacturing site at Rue Jakob-Stampfli 96 in Bienne, Switzerland. The company, which we know today as OMEGA, has remained at the same location ever since. Over the years, the buildings and capabilities have continued to grow and this factory is certainly one of the most important. Here, we give you a behind-the-scenes look at the OMEGA Manufacture in Switzerland…

On-site innovation

OMEGA’s modern factory at its HQ site in Bienne represents today’s most cutting-edge facility for watch assembly, training and quality control. Designed by the inspiring and award-winning Japanese architect Shigeru Ban, it is an eco-friendly masterpiece built entirely from Swiss spruce and concrete. Inside, OMEGA has used the five floors of space in the most effective way possible, bringing technical innovation and human expertise together for a fully streamlined manufacturing process.

The key benefit for OMEGA is efficiency. The building combines all of the brand’s assembly and testing processes under one roof. It is a complete consolidation of work, meaning that the company’s overall output is maximised for productivity. All steps, including watch assembly, bracelets, and packaging, as well as stock and logistics, are completed inside. In addition to this, the building is designed for training purposes, enabling OMEGA to sharpen and constantly improve the skills of the staff inside. As a new generation of watch buyers emerges, OMEGA has revolutionised its facilities to meet their demands.

The artistry of Shigeru Ban

Known for his structural sophistication and unconventional techniques, Shigeru Ban has established his name as one of the world’s leading and most exciting architects. From curvaceous museum designs in France to a cardboard church in Japan, his work has had a global effect and garnered praise not only from his peers, but also from the likes of “Time” magazine, which cited him as one of the 21st century’s top innovators in the field of architecture and design. By blending the themes of Japanese architecture with western modernism, Ban has established his own unique design approach, and is synonymous with the use of unexpected building materials.

Most famously, his ingenious work with paper and cardboard tubing has led the way for low-cost and recyclable structures. But his architecture has not been limited to these materials alone. His clever and spectacular use of timber and glass can also be seen the world over, including OMEGA’s HQ site in Bienne, Switzerland. In 2014, Ban won the Pritzker Prize, the most prestigious award in architecture, for his significant contributions to architectural innovation and philanthropy. His most significant buildings include the Paper Church in Kobe, Japan; the Japan Pavilion for Expo 2000, Hannover, Germany; Nomadic Museum, New York, USA; Nicholas G. Hayek Center in Tokyo, Japan; Metal Shutter House in New York, USA; and the Centre Pompidou-Metz, France.

Tech-friendly interiors

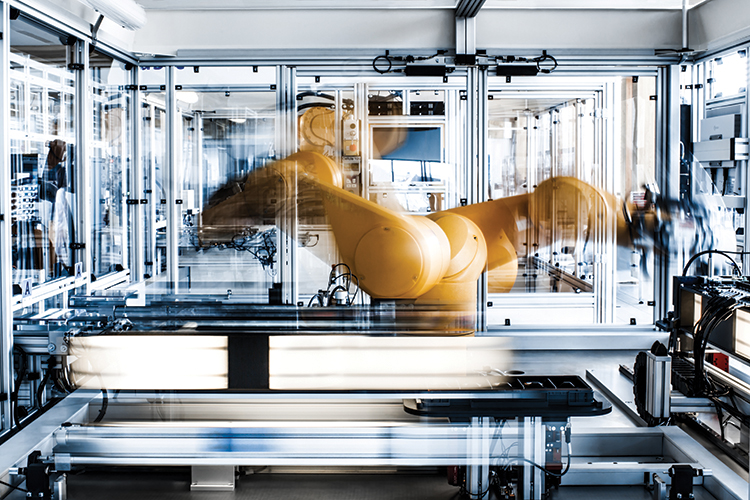

OMEGA’s watchmaking has long been at the forefront of the industry. A glimpse inside its HQ factory reveals how human expertise is now interacting with robotic assistance at the very highest level. At the core of the building, OMEGA has installed a fully automated storage system that rises up through three floors of the building. Like something from a science-fiction movie, the fireproofed central stock contains over 30,000 boxes filled with all the necessary parts required for the brand’s watchmaking. Visitors to the building can marvel at the storage system and its robotic arms in action through specially built windows. Only two specially trained people are authorised to enter the central stock system. This is because the oxygen inside has been reduced to 15.2 per cent to ensure that fires cannot start or spread.

In addition to this, there are several other examples of technology which prove the superb efficiency of OMEGA’s manufacturing today. This includes the robotic arms and systems used for the Master Chronometer testing. For humans, the physical transportation and organisation of the watches is a monotonous and time-consuming job. That’s why OMEGA’s huge robotic arms are completely customised to fulfil the task. By measuring, photographing, winding, shifting and spinning the watches, the robotic arms provide OMEGA with a consistent and constant level of operation. It’s a beautiful assembly line that never misses a beat.

But that’s not to say that the human touch is not needed. While the menial tasks have been given to the robots, OMEGA’s staff can concentrate fully on the testing results and making sure that every watch is finely-tuned and ready for the customer. There are also robotic arms used for the identification and final packaging of each watch. Reader systems ensure that each watch is picked from the assembly line and delivered with the correct warranty and certification, and all other necessary inclusions. Another example of technology includes the arms for laser engraving, which give each watch its unique identity.

Central Stock factsheet

The speed of the central stock is 4 metres per second, while its capacity is more than 30,000 storage boxes. The area has two vertical lifts, with a length of 27.4 metres, a width of 9.4 metres; and a height of 14.2 metres. The Central Stock has a capacity volume of 3,660 cubic metres, while it completes 1,400 operations per hour.

The team of OMEGA Manufacture

The motto “Swiss Made” goes further than describing the pieces of a watch or the company’s technical innovation. They also represent the standard of OMEGA’s people, who work tirelessly to achieve the world’s best watches. Certainly, OMEGA’s greatest strength is its staff. You only need to walk through the factory to see the intense concentration and delicate skills employed at every desk. From setting the hands perfectly on a dial to the final casing of a completed timepiece, the watchmakers all carry the same pride and commitment that has powered the “Swiss Made” OMEGA brand for more than 170 years.

To give its people an added advantage, OMEGA has maximised the working environment of its factory. From carefully managed temperature control to the air conditioning and overall ergonomics, everything has been integrated for an exceptional flow. Even the stringent elimination of dust proves that OMEGA’s manufacturing can operate at a high, and very difficult-to-achieve, standard. By creating this optimum space to work, there is no doubt that OMEGA will excel even further in its watchmaking. After all, it’s this sort of renowned ambition that has made the “Swiss Made” mark so famous around the world. To keep it thriving for the future, OMEGA’s people are in the best position possible.

METAS Testing

OMEGA’s factory has been created to house OMEGA’s quality and technical control processes, including the METAS testing for Master Chronometer certification. All technology for the eight METAS tests can be found on the third floor, including the powerful magnets that subject each watch to a field of 15,000 gauss. It is here that OMEGA certifies its watches at the industry’s highest standard for precision, performance and magnetic resistance.

Green spaces Within OMEGA Manufacture

In keeping with the innovation of this ambitious building project, the factory has been designed with an ingenious indoor climate and energy concept. Following three clear steps, OMEGA has been able to achieve maximum efficiency through a truly sustainable development. Firstly, the insulation level chosen for the building actually exceeds the requirements of the Swiss building code. By relying on this effective, built-in energy, OMEGA can gladly reduce the external loads on the building’s heating system.

On the glass exterior, highly efficient solar shading has been included on each window. These external shading blinds are controlled by the sun, depending on which direction the window is facing. Inside, all artificial lighting is based on LED use. This guarantees low installed power, low electricity consumption and low internal heat loads. The lighting is also controlled by daylight and occupancy-sensors that only switch on when required.

In general, radiant systems have been used for all of the room conditioning. This renowned method offers improved comfort and low energy consumption as the system works based on high cooling temperatures and low heating temperatures. In other words, the heating and cooling of the building can be produced with very high efficiency. In an impressive example of recycling, the factory uses its own excess heat from production processes such as compressed air, vacuums and O2- reduction, for other required areas, such as the preheating of domestic hot water.

Even the fans used in the air-handling unit are energy-efficient to limit electricity consumption. The ventilation rates also vary upon need and are lowered as far as possible at night. Similarly, in the workshops, the air-change rates are controlled differently depending on the specific needs of the production process.

The entire energy supply of the building is based on a geothermal system, which uses the regenerative energy potential of groundwater. This is sourced via several wells on the site. The pumped groundwater runs via a heat exchange to directly cool the rooms. The radiant panels inside the building run with inlet temperatures of 16 to 18°C, which can be supplied directly from the groundwater, without any additional cooling. For heating, the groundwater is controlled with a heat pump.

Finally, to produce some of the electricity needed for heating, cooling, ventilation and renewable lighting, the south-east roof of the building is covered with solar panels. As a world premiere, BLUE AC micro-inverters from Belenos were first used in the creation of the OMEGA factory. These devices are installed directly behind the solar panels, and are directly connected to the electricity network, for which they convert the direct current of the sun into alternating current for the building and thus produce renewable energy. The entire volume of timber used in the production corresponds to just 2.6 hours of tree growth in Switzerland.