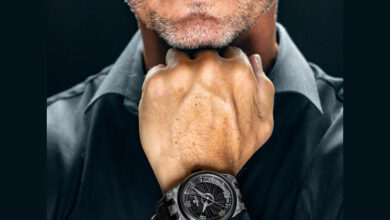

An All Black UR-220 from URWERK

The collection of UR-220 watches has taken off. The initial version in carbon has now been joined by a new model – the UR-220 All Black. URWERK is exploring all the shades of its lucky colour. Black will always be black, but it comes in many textures

With these two watches you can have any colour you like, so long as it’s black. One is made of carbon in patterns reminiscent of crop circles; the other is in a deep, intense black. Both are from the URWERK workshops and belong to the new UR-220 collection.

The UR-220 All Black version is made of titanium and steel. The carbon UR-220 is the first URWERK model in this material and was unveiled last September. Its case, built up in 81 layers of carbon, is unmistakeable.

The main difference between them lies in their weight. The carbon watch, on an avant-garde rubber strap, weighs 25 per cent less than the All Black version, which has a more traditional leather strap. Both watches are built with the same care and attention to detail expected of URWERK’s watchmaking.

On the instrument panel

In a break with tradition, we’ll start with the back of the watch, home to a feature unprecedented and unique in watchmaking – URWERK’s oil change indicator. After an absence of some years, this complication returns to tell you for how long the movement has been running and when it is time to lubricate and service the machinery. Originally in the UR-110 models, the oil change indicator has undergone significant improvements.

In the UR-220 the number of months the movement has been running is shown on two side-by-side rollers. The wearer of the watch starts the count by removing a locking pin and pressing the button on the back of the watch. When the rollers show that the movement has been running for 39 months, it’s time to have the watch serviced. URWERK’s technicians will reset the counter to zero and replace the locking pin.

Riding the carousel

The UR-220 adopts its predecessor’s satellite wandering hours, patented by URWERK. The hours are grouped in fours on three rotating cubes at the end of the carousel arms. In turn they pick up a hollow minutes pointer and carry it across the 120° arc of the minutes scale. At the 60th minute, the pointer flashes back to zero, to be picked up by the next hour. To reduce inertia and increase the speed, the surfaces of the minutes pointer have been pierced. This must be the most sophisticated retrograde minutes indication in any watch.

The lightning-fast fly back of the retrograde minutes depends on three engineering achievements:

The central axis keeps the mechanism stable. Running on ruby bearings, it is the rock on which the complication is built. A cylindrical spring, rather like a traditional chronometer hairspring, accumulates the energy needed to power the fly-back.

The unusual minutes pointer, which forms the cowling for the hours satellites, is precision-engineered to tolerances of a hundredth of a millimetre. With a length of 22.29mm, 8.03mm wide and 7.3mm deep, it weighs just 0.302 grams. Built of aluminium, its bronze counterweight ensures it is perfectly balanced.

Two coaxial star cams govern the retrograde action. Its coupling and rotation determine the trajectory of the minutes pointer. The other information on the dial is the two-stage power-reserve indicator. The time left for the movement to run is shown on two 24-hour gauges. As you wind the watch, the right hand gauge fills up. When it reaches its maximum, the gauge on the left takes over. The mechanism for these two power reserves is extremely intricate, requiring 83 mechanical components.

The smallest detail

No detail can be neglected, especially not the numerals of the UR-220. Martin Frei has designed a new typography, making the hours and minutes even sharper. They find their inspiration in the graphics of contemporary video science-fiction games.